Digital Twins + AI: The Future of Smart Manufacturing and Operations

Author: Zahra Hassan

The manufacturing world is currently witnessing an AI-native renaissance, where the digital and physical worlds merge to create factories that think, learn, and adapt. For decades, manufacturing was defined by small, incremental gains; but today, companies are reimagining entire facilities as intelligent systems to gain a massive competitive edge. At the heart of this transformation is the powerful synergy between Artificial Intelligence (AI), the Internet of Things (IoT), and Digital Twins.

What is a Digital Twin?

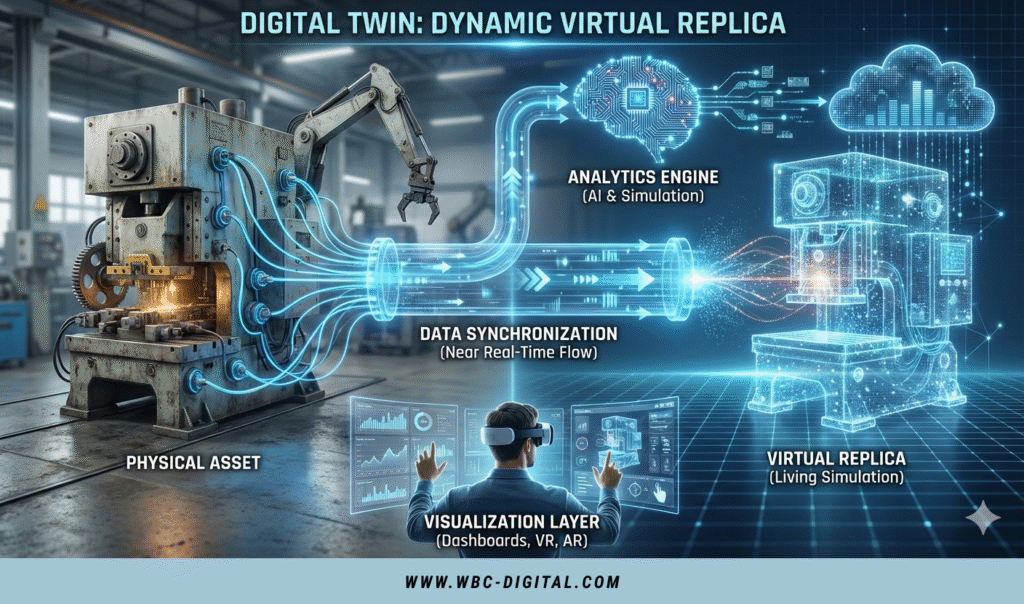

A digital twin is a dynamic virtual replica of a physical object, process, or system that mirrors its real-world counterpart in near real time. Unlike a static 3D model, a digital twin is a living simulation that evolves alongside the physical asset throughout its entire lifecycle. It acts like a virtual sandbox, allowing manufacturers to test scenarios without touching actual equipment.

The core components of a digital twin architecture include:

• Physical Asset: The actual machine, production line, or factory equipped with sensors.

• Virtual Replica: A high-fidelity digital model that captures the asset’s structure and behavior.

• Data Synchronization: A continuous flow of information through pipelines that keeps the virtual model updated with real-time sensor data.

• Analytics Engine: Often powered by AI, this brain processes data to detect patterns and simulate outcomes.

• Visualization Layer: Dashboards or immersive VR (Virtual Reality) or AR (Augmented Reality) interfaces that allow people to interact with the twin.

Understanding AI-Powered Digital Twins

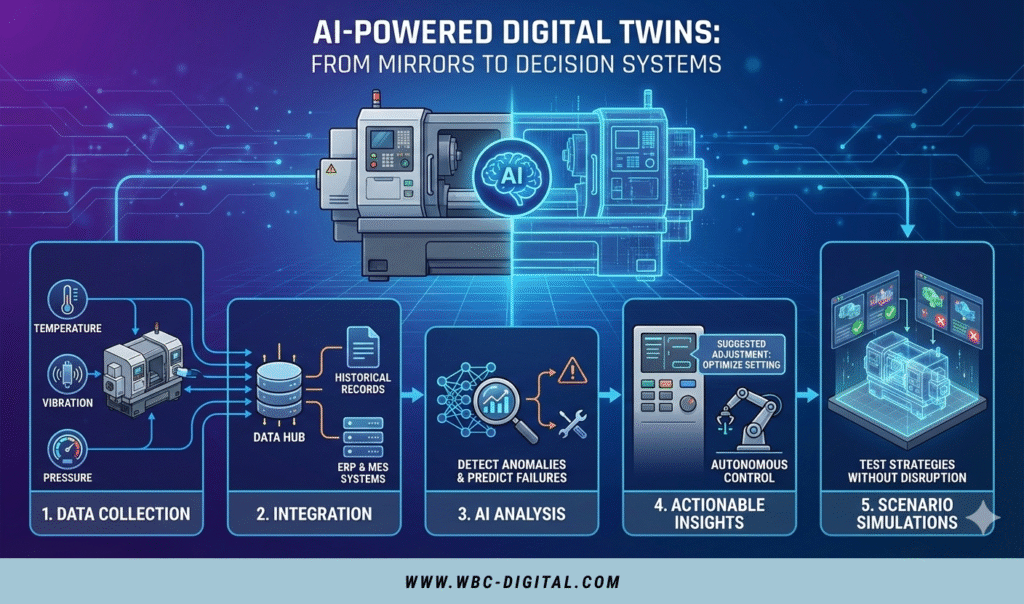

AI transforms digital twins from passive mirrors into active decision-support systems. While a basic twin might show you what is happening now, an AI-powered twin uses machine learning to predict what will happen next and suggest optimizations.

Here’s how it works:

1. Data Collection: IoT sensors capture parameters like temperature, vibration, and pressure.

2. Integration: This data is combined with historical records and enterprise systems such as ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems).

3. AI Analysis: Machine learning models analyze the data to detect anomalies and predict failures.

4. Actionable Insights: The system suggests adjustments or takes autonomous control to maintain peak performance without human intervention.

5. Scenario Simulations: Digital twins run simulations to test different adjustments and strategies without disrupting actual operations.

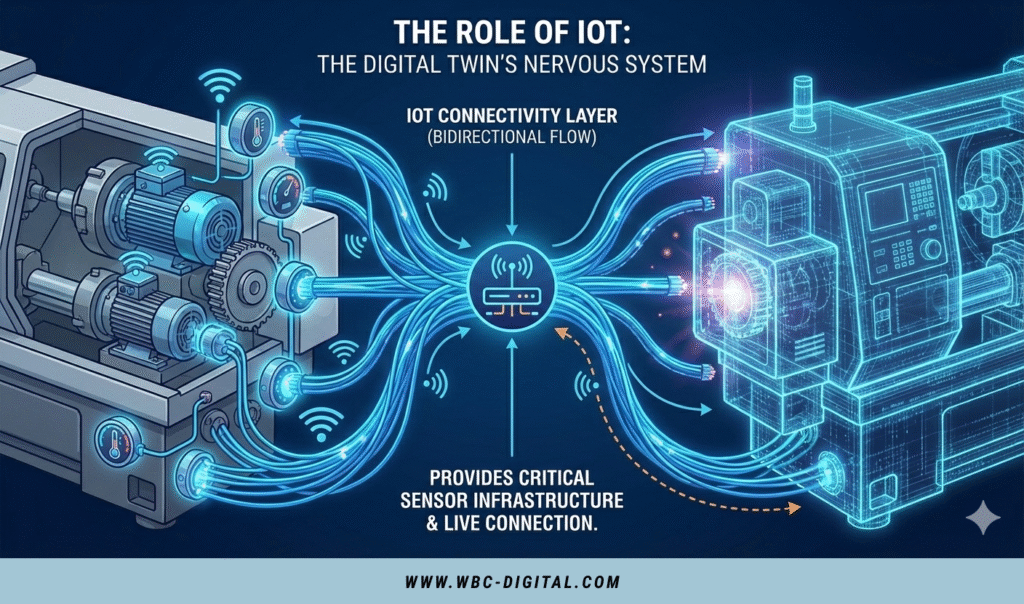

The Role of IoT in Digital Twin Architecture

The Internet of Things (IoT) serves as the foundational nervous system for digital twins. It provides the critical sensor infrastructure and connectivity required to bridge the physical and digital worlds. In a digital twin architecture, IoT forms the data connectivity layer, enabling a continuous, bidirectional flow of information between physical assets and their replicas. Without this live connection, a digital twin would quickly become an outdated, static simulation.

The Software: The Brain Connecting IoT to the Twin

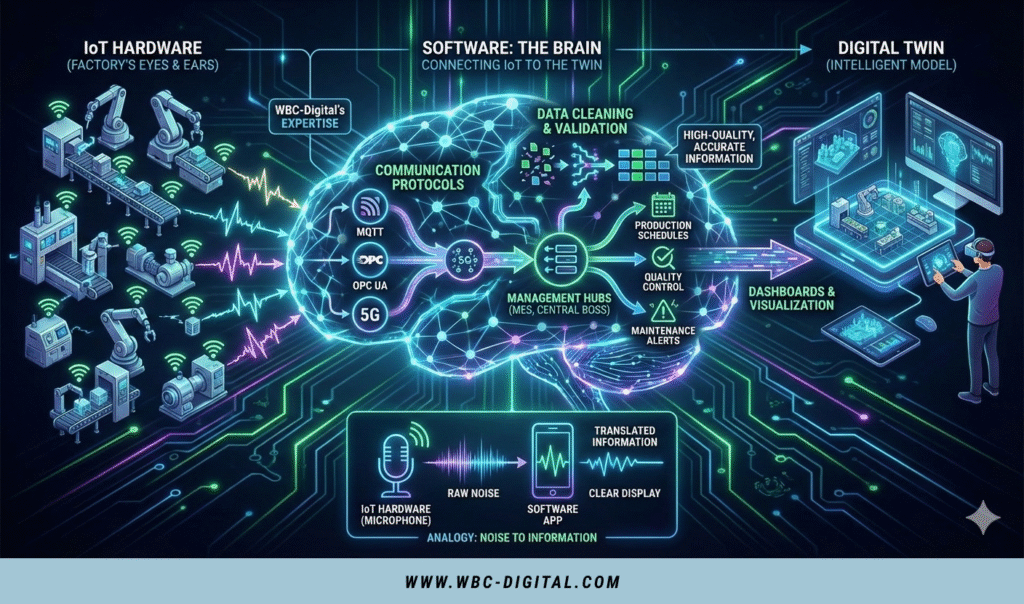

While sensors act as the factory’s eyes and ears, software is the invisible engine that makes that hardware useful. It serves as the bridge that translates raw electrical signals from machines into an intelligent digital model. This is where WBC-Digital’s expertise comes into play.

• Communication Protocols: Software acts as a translator, using languages like MQTT (Message Queuing Telemetry Transport – Messaging protocol for IoT), OPC UA (Open Platform Communications Unified Architecture – Universal translator for industrial machines), or 5G to ensure machines from different brands can all talk to the digital twin.

• Data Cleaning and Validation: Sensors can sometimes provide messy data due to errors or connection drops. Software algorithms automatically detect and fix these gaps, ensuring the virtual model always has high-quality, accurate information.

• Management Hubs: Software platforms like Manufacturing Execution Systems (MES) act as the central boss. They organize all the incoming data so it can be used to plan production schedules, manage quality control, and trigger maintenance alerts.

• Dashboards and Visualization: This software creates the TV screens and immersive interfaces (like Virtual Reality) that allow workers to interact with and control the factory from a computer or tablet.

To make it more clear, here’s an analogy: If IoT hardware (sensors) is the microphone picking up the sounds of a factory, the software is the app that cleans up the background noise, translates the sounds into a language you understand, and displays the information clearly on your phone screen. Without the software, the microphone would just be producing raw noise that no one could use.

Operational Benefits of IoT Integration

Integrating IoT into manufacturing processes offers several immediate advantages:

• Real-Time Visibility: IoT devices provide granular tracking of inventory, warehouse status, and goods in transit, which is critical for just-in-time strategies.

• Asset Health Monitoring: Sensors track parameters like temperature, vibration, and pressure, allowing for the detection of anomalies before they cause shutdowns.

• Energy Management: IoT tracks real-time power consumption, identifying waste and helping manufacturers meet sustainability goals.

• Workforce Safety: Wearable sensors can monitor employee fatigue, heat stress, or ergonomic risks, while digital twins simulate hazardous scenarios to design safer workflows.

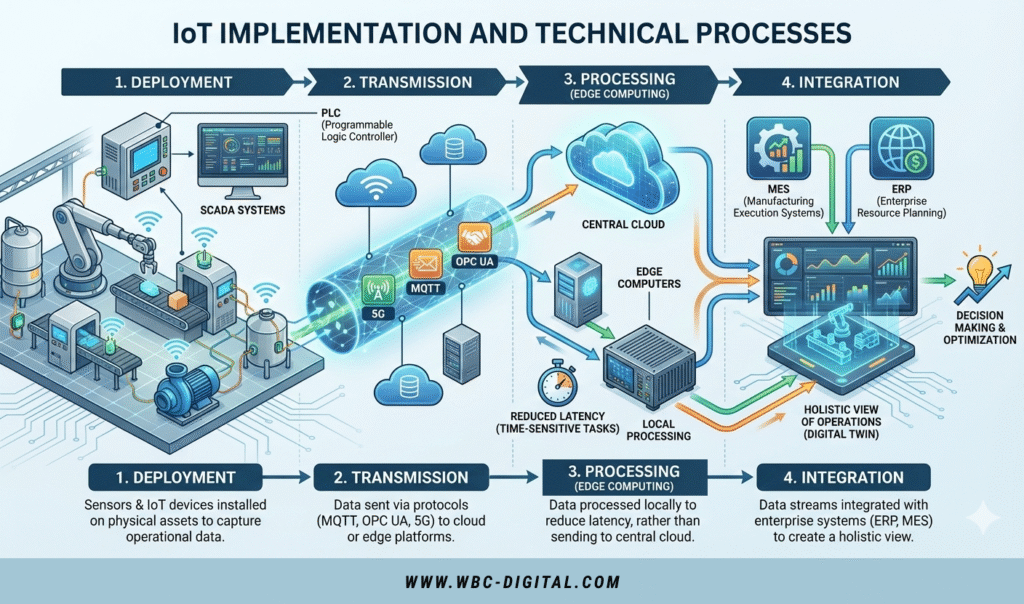

IoT Implementation and Technical Processes

Setting up an IoT-enabled digital twin involves a structured technical process:

1. Deployment: Sensors and IoT devices such as PLCs (Programmable Logic Controller) or SCADA systems (Supervisory Control and Data Acquisition) are installed on physical assets to capture operational data.

2. Transmission: Data is sent via communication protocols like MQTT, OPC UA, or 5G to cloud or edge computing platforms.

3. Processing (Edge Computing): To reduce latency for time-sensitive tasks like robotic guidance, manufacturers use edge computers to process data locally rather than sending it to a central cloud.

4. Integration: These data streams are integrated with enterprise systems like ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems) to create a holistic view of operations.

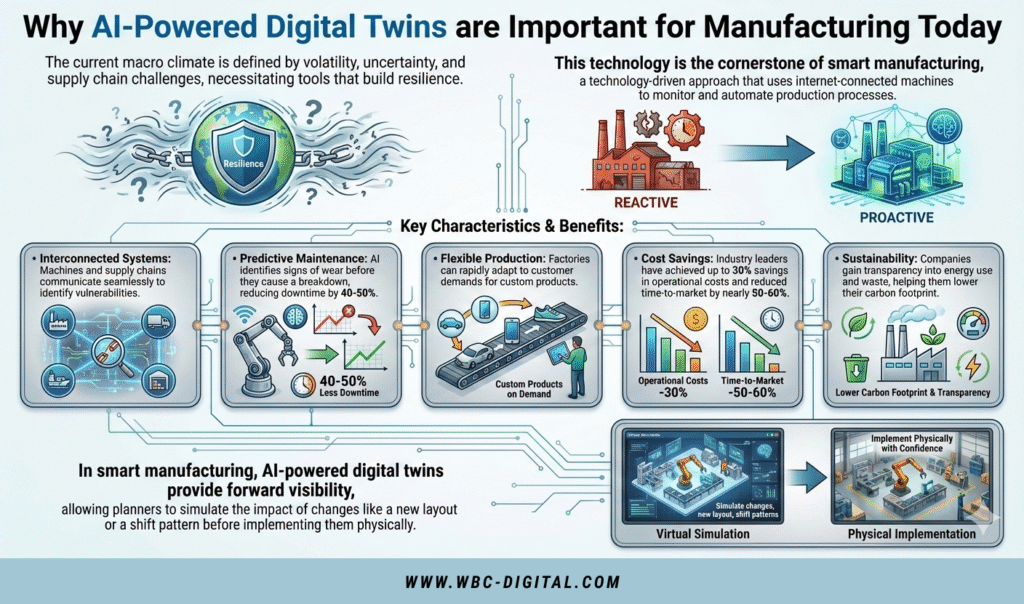

Why AI-Powered Digital Twins are Important for Manufacturing Today

The current macro climate is defined by volatility, uncertainty, and supply chain challenges, necessitating tools that build resilience. This technology is the cornerstone of smart manufacturing, a technology-driven approach that uses internet-connected machines to monitor and automate production processes. It moves factories from being “reactive” to “proactive”.

Key Characteristics & Benefits:

• Interconnected Systems: Machines and supply chains communicate seamlessly to identify vulnerabilities.

• Predictive Maintenance: AI identifies signs of wear before they cause a breakdown, reducing downtime by 40-50%.

• Flexible Production: Factories can rapidly adapt to customer demands for custom products.

• Cost Savings: Industry leaders have achieved up to 30% savings in operational costs and reduced time-to-market by nearly 50-60%.

• Sustainability: Companies gain transparency into energy use and waste, helping them lower their carbon footprint.

In smart manufacturing, AI-powered digital twins provide forward visibility, allowing planners to simulate the impact of changes like a new layout or a shift pattern before implementing them physically.

Challenges of Digital Twins in Smart Manufacturing

Implementation is not without hurdles. Organizations must navigate:

• High Initial Costs: Upfront investments in sensors, software, and AI integration can range from $200,000 to over $5 million for large deployments.

• Data Security and Privacy: Continuous connectivity increases exposure to cyberattacks and requires robust encryption to protect intellectual property.

• Integration Complexity: Many factories rely on legacy systems (old machines) that often lack the necessary sensors or APIs to connect with modern digital platforms.

• Skill Shortage: There is a high demand for specialists like data scientists and IoT architects who know how to manage these systems.

How to Measure the Success of a Digital Twin Strategy?

Success should be measured by the business problems the technology was meant to solve. Key indicators include:

• Overall Equipment Effectiveness (OEE): Early adopters report OEE improvements of 12–18% within 18 months.

• Downtime Reduction: Most companies see a 40% reduction in unplanned downtime.

• Return on Investment (ROI): 92% of companies report returns above 10%, with over half reaching 20% or more.

• Time-to-Market: Digital twins can reduce the time it takes to develop a new product by nearly 60%.

Real-World Application of Digital Twins in Smart Manufacturing

Top manufacturers are already leveraging these technologies to gain a competitive edge:

• Tesla: Every vehicle has its own digital twin powered by sensors to predict breakages and improve the customer warranty experience.

• Siemens: Uses digital twins to optimize every step of lithium-ion battery manufacturing and to develop world-record electric aircraft motors.

• Boeing: Engineers use twins for aircraft design, simulating parts over their entire lifecycle to reduce defects and optimize cargo load.

• General Electric (GE): Employs digital twins to monitor gas turbines, predicting failures and optimizing performance in real time.

• Shell: Uses real-time data from offshore platforms to simulate what-if scenarios, boosting both production and safety.

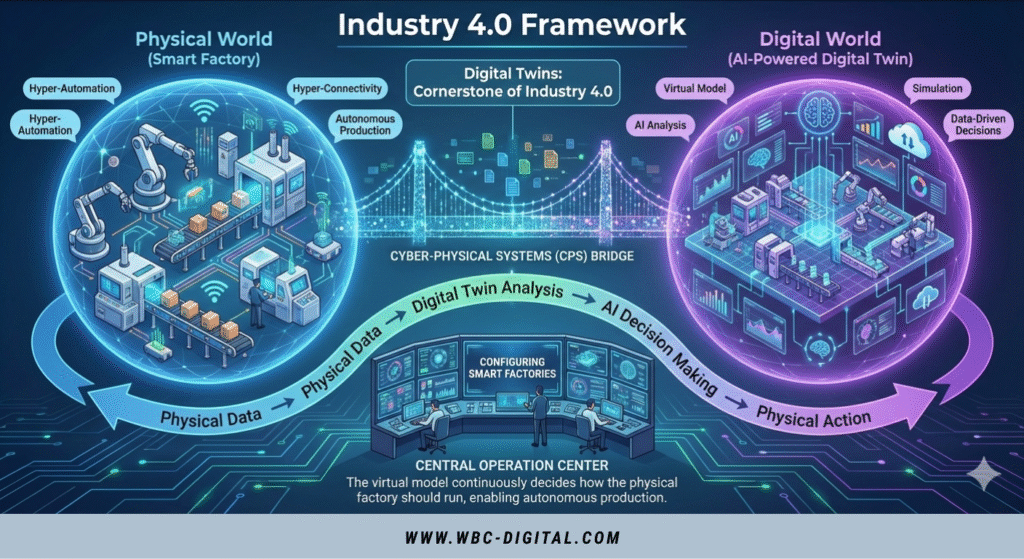

Role of AI-Powered Digital Twins + Smart Manufacturing in Industry 4.0

Digital twins are the cornerstone of Industry 4.0, bridging the physical and digital worlds to enable Cyber-Physical Systems (CPS). They serve as a central operation center that allows for the configuration of Smart Factories, where hyper-automation and hyper-connectivity make autonomous production possible. This integration fosters a physical-digital-physical journey, where the virtual model continuously decides how the physical factory should run.

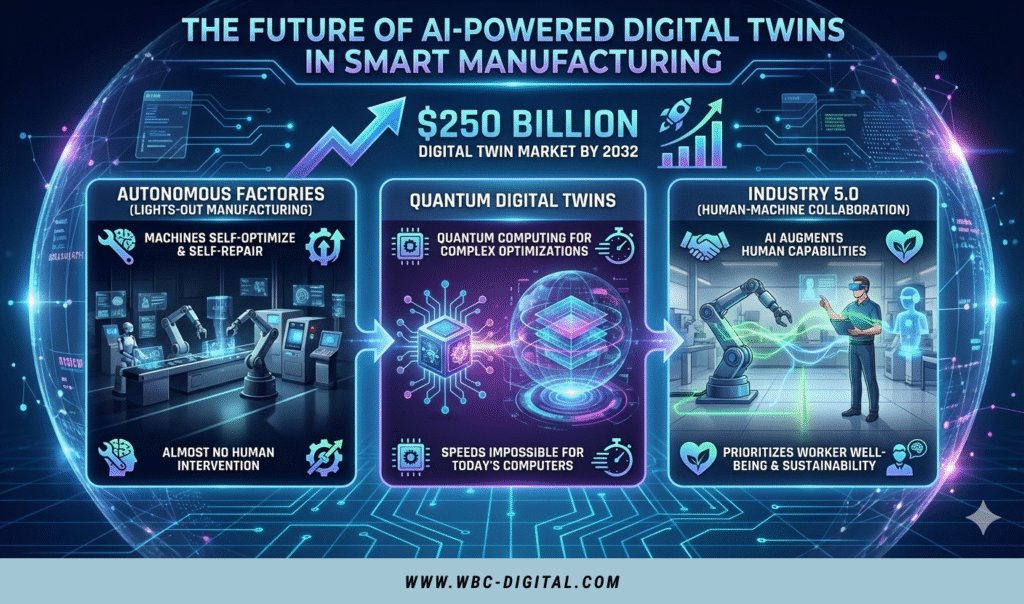

The Future of AI-Powered Digital Twins in Smart Manufacturing

The digital twin market is expected to skyrocket to over $250 billion by 2032. Emerging trends include:

• Autonomous Factories: Moving toward lights-out manufacturing, where machines self-optimize and self-repair with almost no human intervention.

• Quantum Digital Twins: Using quantum computing to solve complex optimizations at speeds impossible for today’s computers.

• Industry 5.0: Shifting toward human-machine collaboration, where AI augments human capabilities and prioritizes worker well-being and sustainability.

Conclusion

AI-powered digital twins are no longer a futuristic concept; they are a business imperative for manufacturers who want to stay competitive. By creating a living digital mirror of their operations, companies can reduce costs, innovate faster, and build more resilient supply chains.

Think of an AI-powered digital twin as a flight simulator for a factory. Just as a pilot uses a simulator to practice dangerous landings in a safe environment, a manufacturer uses a digital twin to test every possibility, from a machine breaking to a supply chain delay, ensuring that when they fly the real factory, everything goes perfectly.

Ready to bridge the gap between data and action? Sign up for a free consultation to learn how integrating IoT and AI can eliminate downtime and streamline your production. Move beyond reactive fixes and start leading with foresight.

WBC Digital Solutions

Book a Consultation

Ready to take the next step? Schedule a consultation with our expert team.

Explore Related Topics

Other Articles

WBC Digital Partners with Great Wall Connect to Unlock China’s Digital Market

WBC Digital is partnering with Great Wall Connect to deliver end-to-end digital solutions for companies expanding into China.

Read more →

AI in Industrial IoT: How It’s Revolutionizing Asset Management

Exploring AI in asset management? Discover its growing role, industry impact, and what it means for the future of business.

Read more →

How E-Commerce Businesses Can Leverage Data to Maximize Sales This Chinese New Year

Let's explore how you can use your data to maximize sales in Chinese New Year.

Read more →